DFC Industry

NERO — the embodiment of a strategic transformation

When a Market Turns Faster Than Its Incumbents

DFC Industry had long been a cornerstone of the Champagne ecosystem.

As an importer, distributor, and maintenance leader, DFC built deep trust with Champagne Houses and independent growers alike, servicing the most advanced machinery used in vineyards with extreme constraints.

But the market was shifting — fast.

What had once been a stable value chain began to fracture under structural pressure from manufacturing delays, price inflation, and new industrial entrants with far greater production capacity.

DFC didn’t face a branding problem.

It faced a systemic one.

Case Study Tags

Industrial Strategy | Industry Analysis | Mechanical Engineering | Industrial Engineering | Industrial Design | Tracked Vehicle Systems | Prototyping | Manufacturing Strategy | Part Sourcing | CE Certification | Technical Documentation | Product Launch

Studio

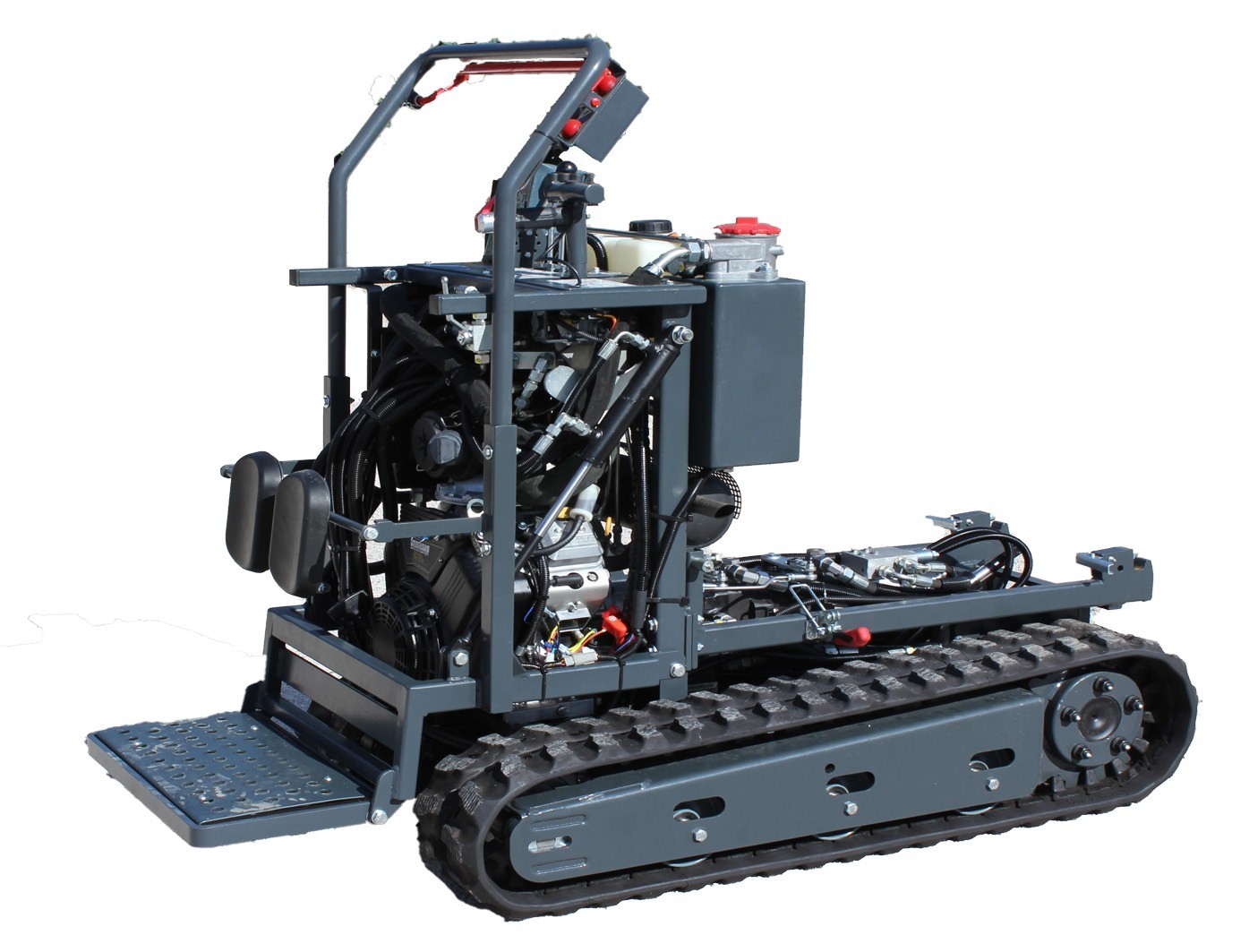

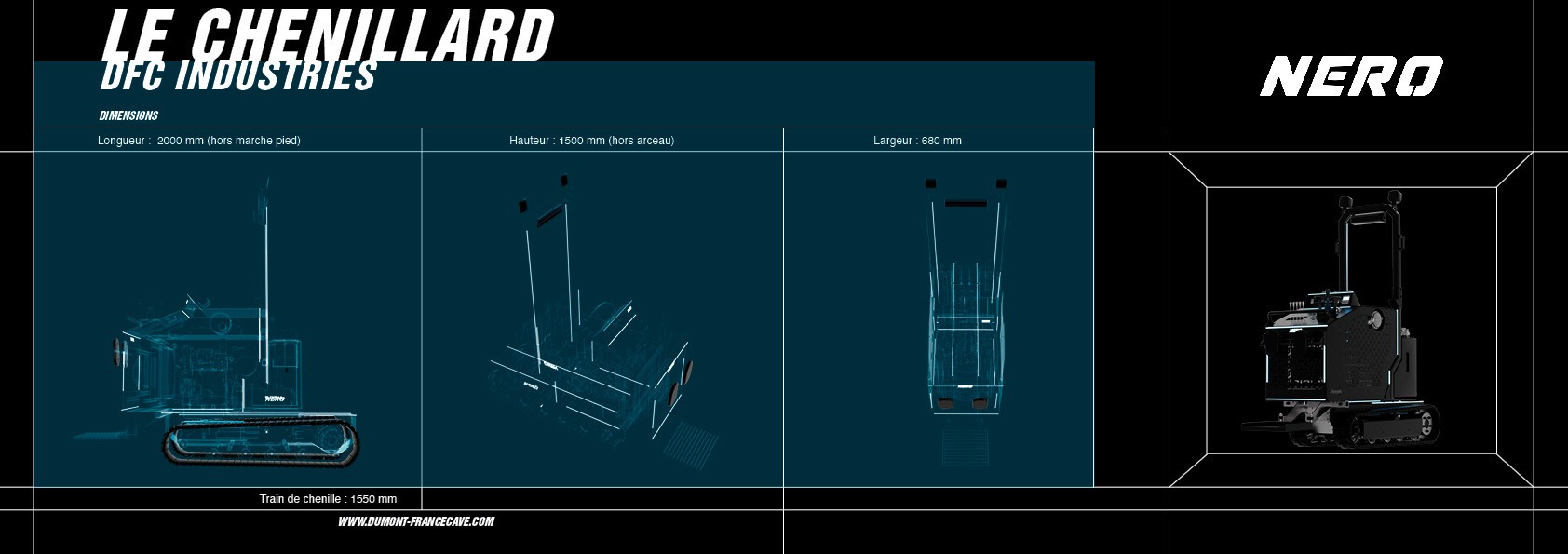

Paris

Designed as an ultimate track vehicle, NERO redefines vineyard mobility and efficiency—offering stability, adaptability, and precision where wheeled systems struggle. It is not an incremental upgrade, but a structural rethink: a machine engineered for the realities of modern viticulture and the economics of a new agricultural era.

With NERO, DFC Industry transitions from supporting the Champagne ecosystem to actively shaping its future—through manufacturing, innovation, and purpose-built engineering.

When an Industry Moves Faster Than Its Tools

For years, DFC Industry sat at the heart of the Champagne ecosystem, maintaining and distributing the most advanced vineyard machinery in the region. The model worked — until it didn’t.

The enjambeur tractor (i.e. high clearance tractors), long the backbone of DFC’s revenue, became a bottleneck. Delivery times stretched to nearly two years. Prices climbed. And Champagne houses, once willing to wait and pay a premium, began questioning whether the equation still made sense. Operational planning grew harder. Capital expenditure became harder to justify.

At the same time, new competitors entered the market from the broader agricultural industry. Backed by heavier manufacturing capabilities, they moved faster, produced cheaper machines, and delivered on timelines Champagne producers could no longer ignore.

Meanwhile, another shift was already underway. Tracked vineyard vehicles — chenillards — were gaining ground, particularly in steep or complex terrains where traditional tractors struggled. DFC knew this space well from a maintenance standpoint, but as a distributor it arrived too late. The most competitive brands were already locked, and the alternative available proved misaligned with Champagne’s technical and economic realities.

Structural Dependence on Enjambeur Tractors

More than 50% of DFC’s annual revenue depended on enjambeur tractorsNew Competitors, New Economics

A Changing Client Reality

A Missed Transition Opportunity

DFC had deep technical expertise — but no product aligned with its market.

From Distributor to Manufacturer

DFC engaged Ateliersavant not to “design a machine”, but to rethink its role in the industry.

The objective was clear:

Analyze the entire competitive landscape

Identify structural gaps and under-served needs

Determine whether DFC should continue distributing — or become a manufacturer

The conclusion was unequivocal.

To remain relevant, DFC needed to own the next generation of vineyard mobility.

Industry-wide Mapping

We conducted a full analysis of:

1. Existing chenillard platforms

Their mechanical, ergonomic, and operational limitations

Cost structures, delivery cycles, and serviceability

Compatibility with Champagne vineyard constraints (slopes, spacing, soil impact)

Defining the Opportunity Space

From this analysis emerged a clear opportunity:

A tracked vehicle engineered specifically for Champagne

Designed for extreme slopes

Modular, accessory-compatible, and future-proof

Positioned between operator control, remote operation, and long-term AI autonomy

Designing for Today — And Tomorrow

From the outset, NERO was designed with evolution in mind.

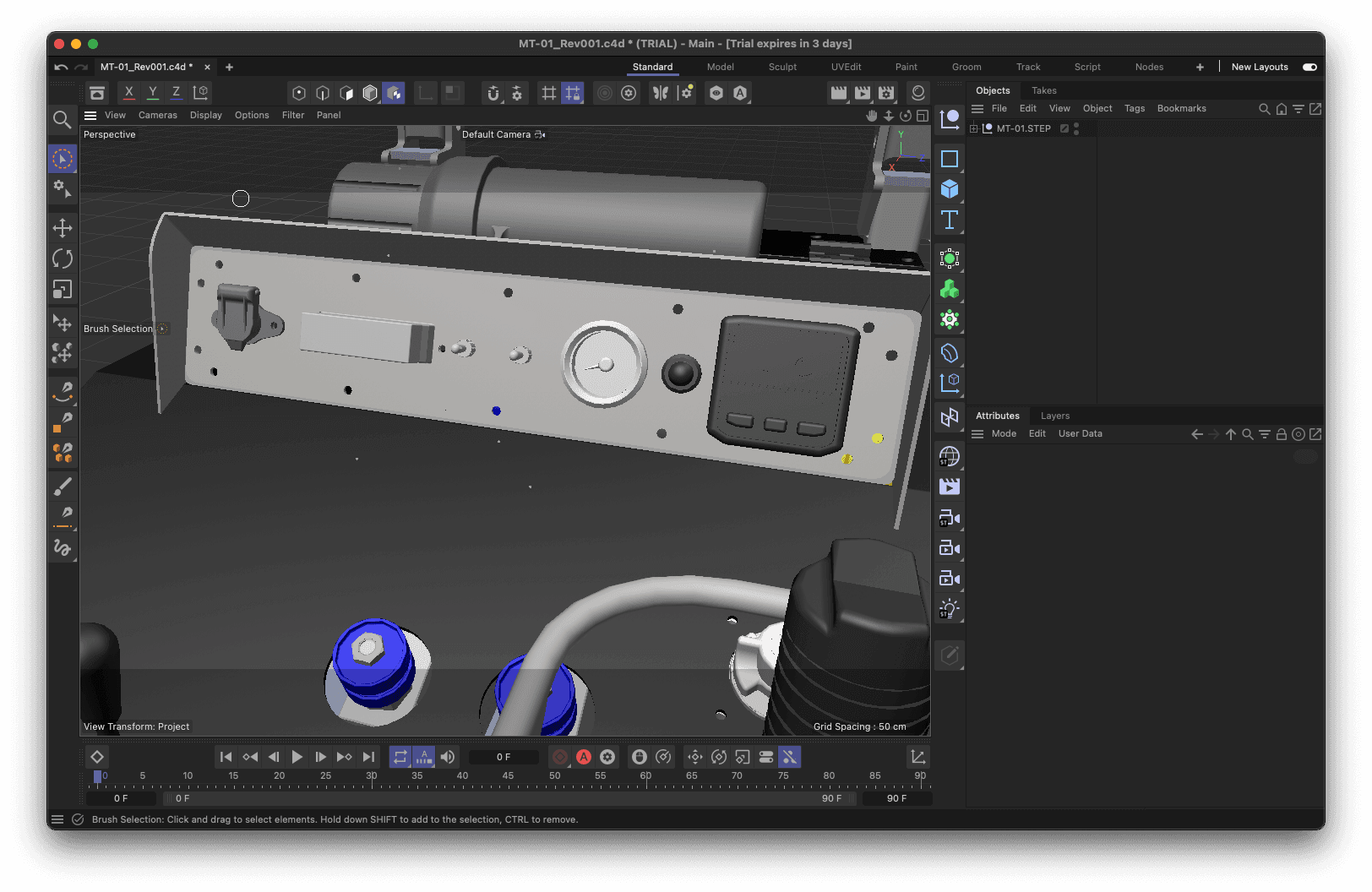

Ateliersavant led the full industrial design and engineering process, developing multiple iterations of the machine architecture while sourcing and integrating best-in-class technologies across propulsion, traction, control systems, and modular accessories. Close collaboration with DFC’s long-standing partners — including accessory manufacturers such as Boisselet — ensured full compatibility with existing equipment and sales verticals.

Beyond mechanical performance, the system was conceived as a roadmap: starting as a fully operator-controlled machine, then progressively enabling remote operation, and ultimately paving the way toward AI-assisted vineyard workflows.

This approach allowed DFC to invest once, while unlocking long-term technological leverage.

Prototyping in the Real World

Two major prototyping cycles anchored the development.

The first validated core engineering decisions, mechanical robustness, and manufacturability. The second was shaped by reality: an entire growing season of field testing with heavy professional users, operating the machine under real Champagne conditions.

Feedback from this phase directly informed the final revisions — from ergonomics and traction behavior to maintenance access and operational safety. Every iteration brought the machine closer to its users, not just its specifications.

From Product to Market

Ateliersavant’s role extended well beyond design and engineering.

We supported DFC through the full launch ecosystem: defining the product narrative, producing technical documentation, structuring certification pathways, developing advertising assets, and preparing trade show and commercial rollout strategies.

The objective was not simply to launch a machine, but to position DFC as a credible industrial innovator — capable of competing with established agricultural manufacturers while remaining deeply rooted in the Champagne industry.

A Strategic Shift, Made Tangible

With NERO, DFC Industry transitioned from dependency to ownership.

What began as a response to market pressure became a long-term strategic asset: a proprietary machine, built for a specific terrain and clientele, scalable over time, and aligned with the future of automated viticulture.

More than a product, NERO represents a shift in posture — from reacting to supply constraints to shaping the next chapter of vineyard mobility.